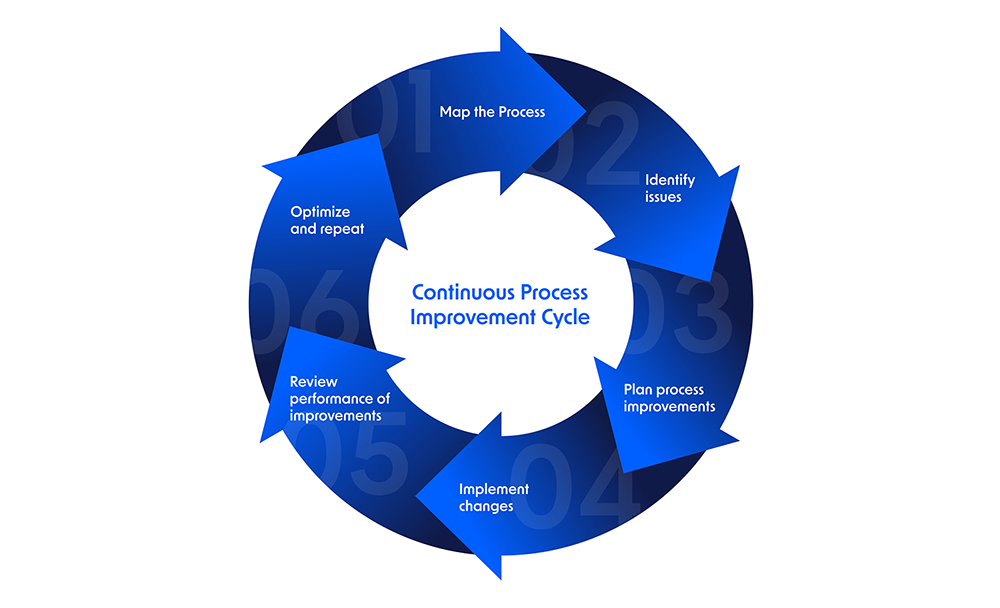

In today's competitive world, organizations that can continuously monitor, evaluate, and improve their processes are more successful. The concept of Continuous Process Improvement (CPI) means making gradual, continuous, and purposeful changes in organizational processes to increase productivity, quality, and customer satisfaction.

This article provides a comprehensive definition of CPI, its relationship with Business Process Management (BPM), and introduces its key tools so that the path of continuous improvement in your organization can be implemented scientifically and practically.

Definition and Philosophy of Continuous Process Improvement

Continuous Process Improvement (CPI) is a management approach that emphasizes small, continuous, and measurable changes instead of sudden and large-scale changes. The core philosophy of CPI is based on the belief that no process is perfect and there is always an opportunity for improvement.

This approach, unlike Business Process Reengineering (BPR), which seeks fundamental changes, focuses on gradual reforms without disrupting ongoing activities. In organizations that utilize BPM, CPI is recognized as the final step to maintain the dynamism and agility of processes.

- Focus on small yet continuous changes

- Involvement of all employees in the improvement process

- Reliance on data and statistical evidence for decision-making

- Integration with technology and analytical tools for performance monitoring

Relationship of CPI with Business Process Management (BPM)

Business Process Management (BPM) is a comprehensive framework for designing, executing, monitoring, and optimizing organizational processes. CPI is essentially the last link in the BPM Lifecycle and ensures that processes continuously improve after implementation.

In other words, BPM provides the structure and tools, while CPI acts as the driving engine of this system, keeping the organization on the path of growth and continuous optimization.

- BPM defines the process path; CPI improves it.

- BPM provides measurement tools; CPI uses them for decision-making.

- BPM has a recurring cycle, with CPI at its core dynamics.

Key Tools in Continuous Process Improvement

To successfully implement Continuous Process Improvement, organizations use a set of managerial and analytical methods and tools. Here are the most important ones:

1. PDCA Cycle

The Plan – Do – Check – Act cycle is one of the oldest and most effective continuous improvement tools. This model helps organizations implement changes in a controlled manner through a staged design.

- 📋 Plan: Identify the problem and plan to solve it

- ⚙️ Do: Implement changes on a small scale

- 🔍 Check: Evaluate the results and compare with goals

- 🚀 Act: Generalize successful solutions to the entire organization

2. Kaizen Method

The Japanese word Kaizen means "change for the better." This method focuses on the collective participation of employees in identifying and implementing improvement ideas. Kaizen is particularly effective in manufacturing and service industries for reducing waste and increasing productivity.

3. Six Sigma Method

Six Sigma is a statistical approach for reducing errors and variations in processes. By using the DMAIC method (Define, Measure, Analyze, Improve, Control), organizations can achieve near-perfect process performance.

4. Lean Method

Lean focuses on eliminating waste, simplifying work processes, and improving value flow for the customer. This method plays a significant role in enhancing productivity in manufacturing, logistics, and service industries.

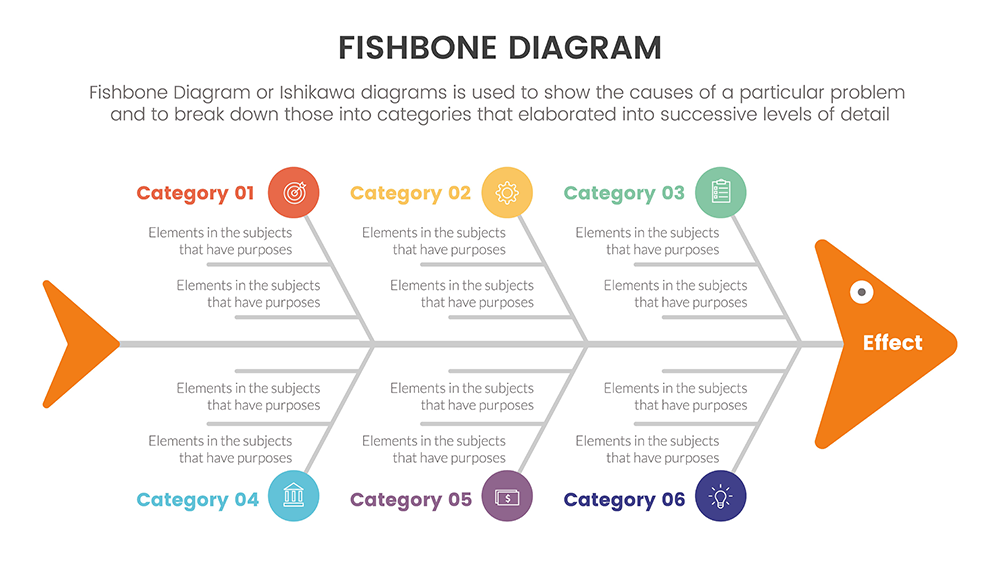

5. Root Cause Analysis (RCA)

To achieve sustainable improvement, the root cause of problems must be identified. Tools like "5 Whys" and "Ishikawa Diagram" help organizations find the roots of errors and eliminate them.

Benefits and Outcomes of Implementing Continuous Process Improvement

Proper implementation of CPI in organizations leads to increased productivity, reduced costs, and improved service quality. Tangible results of continuous improvement include:

- Increased productivity of employees and processes

- Reduction in errors and waste in operations

- Enhanced quality of products and services

- Increased satisfaction of customers and stakeholders

- Data-driven decision-making and statistical evidence

- Support for digital transformation and process automation

In fact, Continuous Process Improvement is not a temporary project but an organizational culture intertwined with Business Process Management (BPM), ensuring the long-term sustainability of the organization's competitiveness.

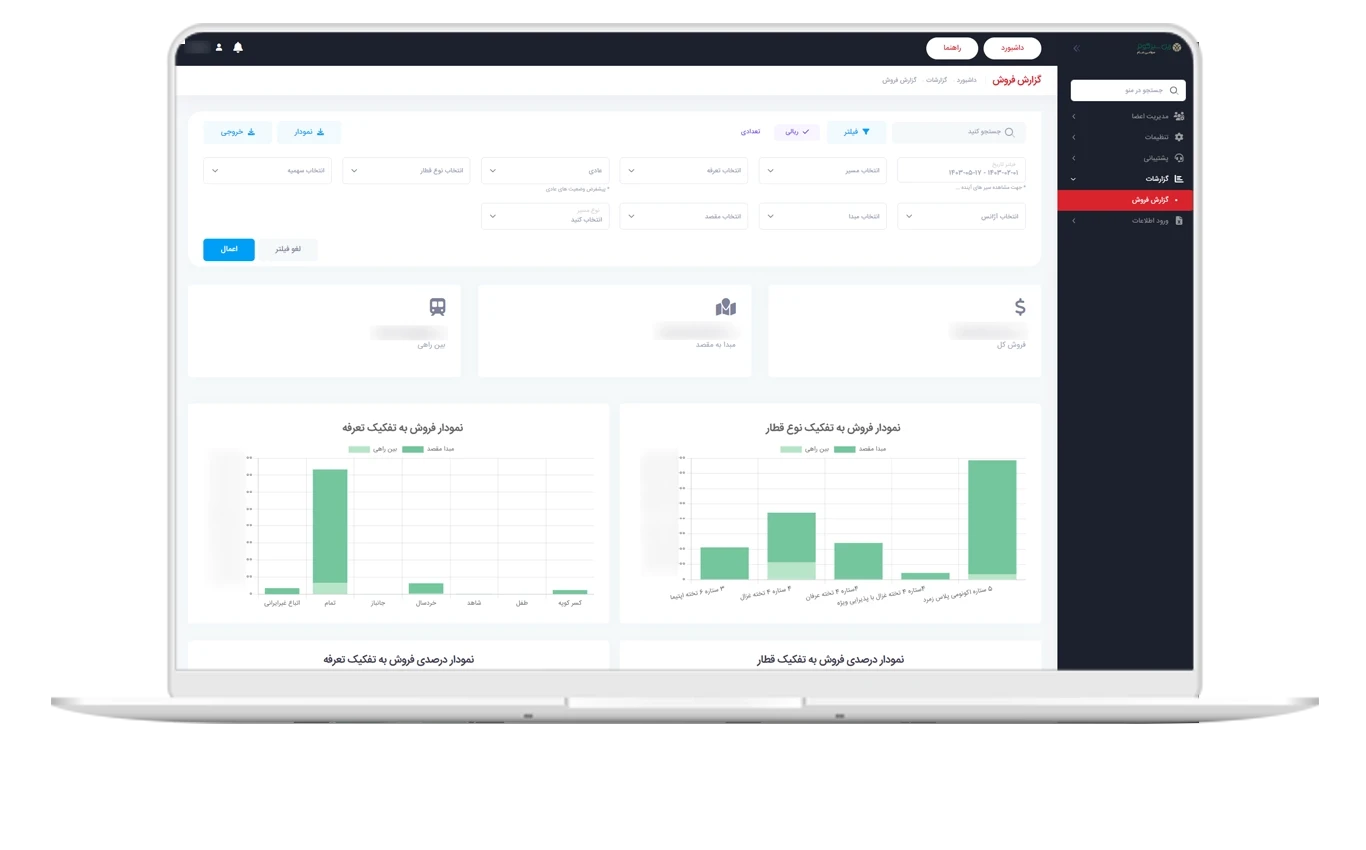

Software Tools Supporting CPI

In the digital age, BPMS (Business Process Management Systems) play a crucial role in implementing continuous improvement programs. These systems provide capabilities such as performance monitoring, process simulation, and operational data analysis, creating an essential foundation for more precise decision-making.

- 📊 Analytical dashboards for monitoring KPIs

- 🔍 Simulation engines for testing changes before implementation

- ⚙️ Workflow Engine for automating processes

- 📈 Reporting tools for ongoing evaluation

Conclusion

Continuous Process Improvement (CPI) is one of the fundamental pillars of success for modern organizations. This approach integrates organizational culture, management tools, and BPM technologies to enable sustainable growth and long-term productivity.

Organizations that systematically work on improving their processes consistently stay one step ahead of their competitors. For effective CPI implementation, it is recommended to utilize digital infrastructure such as Business Process Management System (BPM) to accurately and effectively carry out the ongoing optimization of processes.

Frequently Asked Questions

The PDCA cycle and the Kaizen method are very suitable for initiating continuous improvement in organizations.