On the path of Business Process Management (BPM), organizations are always faced with the question: “What is the current state of our processes and how can we bring them to the desired level?” The answer to this question depends on the implementation of Gap Analysis; a systematic method for comparing the current state (As-Is) and the desired state (To-Be) in organizational processes.

In this article, we will comprehensively examine what gap analysis is, what steps it includes, how it is used in measuring process maturity, and what role it plays in improving organizational performance.

Introduction to the Concept of Gap Analysis

Gap Analysis is a management tool used to identify the gap between “current performance” and “expected performance” in organizational processes. This method helps managers identify deficiencies, inefficiencies, and weaknesses in processes and design corrective actions to achieve optimal goals.

In simple terms, gap analysis is a response to the following questions:

- How is our process currently being executed?

- What differences exist compared to the desired process?

- How can we eliminate this gap?

Why is Gap Analysis Important in BPM?

Within the framework of Business Process Management (BPM), the main goal is to achieve greater efficiency, agility, and quality in organizational performance. However, without a precise understanding of the current state, any planning for improvement will be aimless. Gap Analysis is the tool that provides this understanding.

The importance of implementing this analysis can be summarized in several key points:

- Measuring the level of process maturity and the organization's readiness for change

- Identifying improvement priorities and critical points in processes

- Reducing optimization costs by focusing on key points

- Increasing accuracy in process redesign

- Supporting data-driven decision-making based on operational realities

Steps for Implementing Gap Analysis

Successful implementation of Gap Analysis requires going through systematic steps. Below are the key steps in this process:

- Define the Objective: It must first be determined what the purpose of the analysis is—speeding up, reducing costs, or improving service quality.

- Document the Current State (As-Is): The current process is modeled and documented accurately at this stage.

- Design the Desired State (To-Be): Using optimization methods and BPM standards, the ideal model is designed.

- Compare Current and Desired States: Differences and gaps are identified and measured in this step.

- Root Cause Analysis of Gaps: Using tools like cause-and-effect analysis, the reasons for the emergence of gaps are examined.

- Develop Improvement Plan: Finally, strategies to reduce or eliminate gaps are formulated and presented in the form of a continuous improvement plan.

Tools and Techniques Used in Gap Analysis

To conduct gap analysis, a set of managerial, statistical, and analytical tools are utilized. Some of the most important ones include:

- Process Map: A visual representation of the current and desired process stages for easier comparison.

- Fishbone Diagram: Used to identify factors affecting performance gaps.

- SWOT Analysis: Examining strengths, weaknesses, opportunities, and threats in process execution.

- Key Performance Indicators (KPI): Measuring the gap between current performance and targeted outcomes.

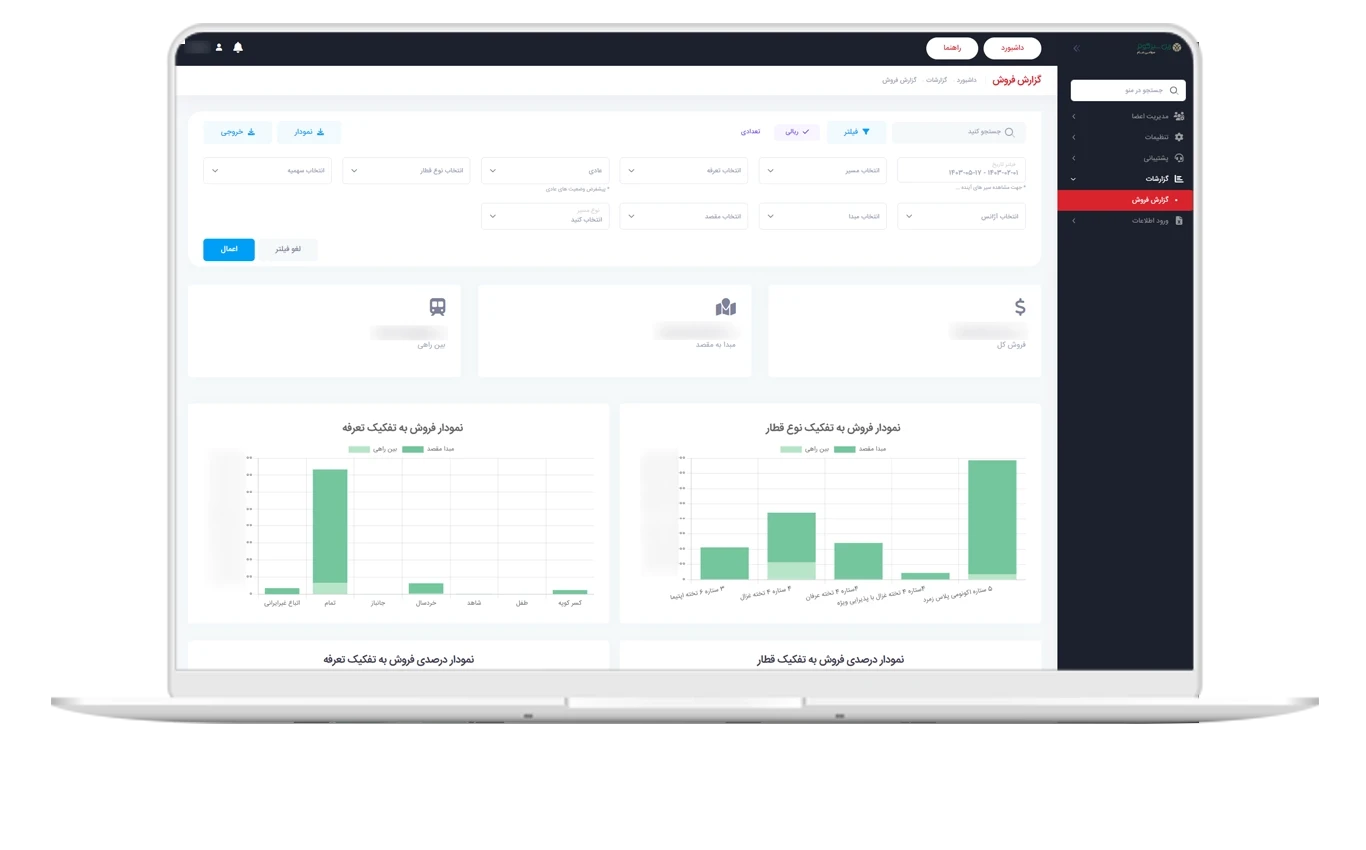

- BPMS Tools: For analyzing real data and identifying bottlenecks based on process logs.

Gap Analysis and Assessment of Process Maturity

One of the important applications of Gap Analysis is measuring the level of process maturity in organizations. Maturity models such as BPMM or CMMI provide a framework for assessing the extent of standardization and optimization of processes.

Organizations can determine their current position in the maturity model by executing Gap Analysis and plan their advancement step by step:

| Maturity Level | Characteristics | Recommended Action |

|---|---|---|

| Level 1 - Initial | Processes are undocumented and reliant on individuals | Documenting and standardizing processes |

| Level 2 - Managed | Processes are controlled with preliminary indicators | Using BPMS tools and automation |

| Level 3 - Standardized | Processes are documented and repeatable | Gap analysis and performance improvement between units |

| Level 4 - Quantitative and Optimized | Improvement is based on data and analyses | Using Process Simulation and combined Gap Analysis |

| Level 5 - Continuous Optimization | A culture of continuous improvement is institutionalized within the organization | Periodic gap analysis and process redesign |

The Role of BPMS in Gap Analysis

BPMS tools can automatically collect real process data and compare them with ideal models. In this way, managers use analytical dashboards to identify gaps and measure performance instead of manual analysis.

Connecting Gap Analysis to the workflow engine and BPMS Workflow enables real-time monitoring of deviations and consequently directs the process toward intelligent optimization.

Benefits of Implementing Gap Analysis in Process Management

- Increased transparency in the performance of organizational units

- Improved managerial decision-making with real data

- Reduced costs and errors resulting from inefficient processes

- Prioritization of improvements based on actual impact

- Increased productivity and alignment with the organization’s strategic goals

Conclusion and Summary

Gap Analysis is one of the fundamental tools in the path of organizational maturity and continuous improvement. This analysis provides a clear roadmap for enhancing performance and achieving organizational goals by identifying the gap between the current and desired states.

Within the framework of Business Process Management (BPM), gap analysis is not just a diagnostic tool but a starting point for transformation in processes. Organizations that regularly implement this analysis will move more rapidly toward agility, productivity, and organizational maturity.

Frequently Asked Questions

A gap analysis is a management tool for identifying the distance between the current and desired states in organizational processes.

Audit focuses on compliance, while gap analysis concentrates on performance gaps and improvement strategies.

Organizations that are on the path of digital transformation and BPM and intend to standardize and optimize their processes.