In today's fast-paced world, data-driven decision-making and predicting organizational performance before it occurs has gained unprecedented importance. One of the most effective tools in this domain is Business Process Simulation, which allows organizations to model, analyze, and optimize their processes in a virtual environment before actual execution. Within the framework of Business Process Management (BPM), simulation plays a vital role in reducing risk, saving costs, and improving organizational efficiency.

Introduction to the Concept of Process Simulation

Process simulation is a technique through which actual business models are recreated in a digital environment in the form of data, workflows, resources, and decision-making. The aim of this process is to examine various scenarios and analyze the impact of managerial decisions before they are executed in the real world.

Simulation is, in fact, a phase of the BPM lifecycle, which occurs after design and before execution. Organizations can use simulation to predict whether their new process will function optimally in real-time or if it requires adjustments.

Why is Process Simulation Important?

Simulation is a tool for reducing decision-making risk and predicting the performance of complex systems. In large and multi-departmental organizations, implementing changes directly without prior analysis may lead to financial loss or operational disruption. As a result, process simulation enables managers to anticipate the consequences of their decisions and choose the best option.

- Reducing trial and error costs in the real environment

- Identifying process bottlenecks before execution

- Evaluating the impact of changes on the overall performance of the organization

- Increasing accuracy in designing new processes

- Facilitating data-driven and scenario-based decision-making

Steps for Implementing Business Process Simulation

Successful simulation requires adherence to systematic and scientific steps. Below, we examine the main cycle of Process Simulation:

- Process Modeling: First, processes must be designed using standards such as BPMN to define workflows and decisions clearly.

- Defining Variables and Resources: In this stage, data such as activity times, costs, human resource capacity, and system capabilities are defined.

- Defining Scenarios: To analyze the impact of changes, various scenarios (such as increased demand or reduced resources) are defined and prepared.

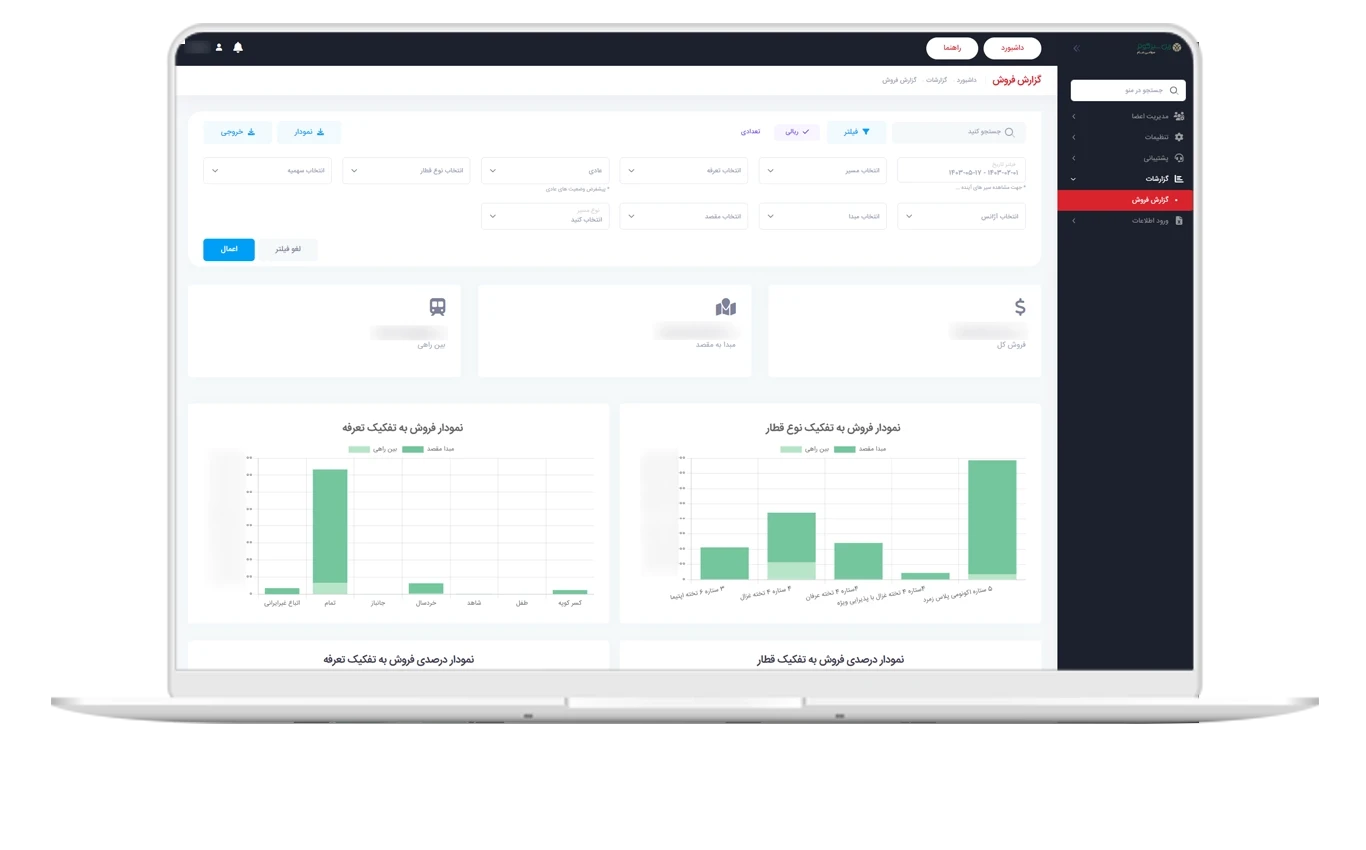

- Executing Simulation: The BPMS Workflow software executes the models and examines their performance under various conditions.

- Analyzing Results: Data obtained from the simulation is analyzed to identify weaknesses, bottlenecks, and optimization opportunities.

- Improving and Redesigning Processes: Finally, processes are adjusted based on the analysis results and re-simulated to achieve optimal performance.

Scenario Analysis in Process Simulation

One of the most valuable capabilities of process simulation is the ability to perform Scenario Analysis. With this capability, various scenarios can be tested to determine how changes in variables such as human resources, workload, or task duration affect overall performance.

For example, in a sales process, scenarios such as increased demand in a specific season or reduced support staff can be simulated and analyzed to identify which situation will yield the highest efficiency at the lowest cost.

Popular Tools for Process Simulation

There are various software options available in the market for simulating and analyzing processes. Some of them are standalone applications, while others are integrated as internal modules in BPMS software.

- Bizagi Modeler: One of the popular tools for modeling and executing simulation scenarios.

- Simul8: A powerful tool for simulating industrial and service processes.

- ARIS Simulation: An advanced tool for analyzing time, cost, and resources.

- Camunda BPM: A workflow engine and simulation tool in organizational environments with integration capabilities with ERP.

Benefits of Process Simulation in Organizations

Utilizing process simulation is not only a management tool but also a transformative strategy for data-driven organizations. Below are the most significant benefits of this approach:

- Continuous improvement of system performance and efficiency

- Reduction of operational costs and prevention of high-risk decisions

- Assessment of the effects of structural changes before implementation

- Predicting scheduling and capacity of organizational resources

- Supporting strategic decision-making with real data analysis

The Relationship of Process Simulation with BPMS and Business Optimization

Within the framework of Business Process Management (BPM), simulation serves as a bridge between design and execution. BPMS Workflow systems utilize real data and analytical algorithms to enable accurate simulation and continuous updating of processes.

This approach guides organizations toward Smart Optimization and automates the cycle of analysis, execution, monitoring, and corrective action. In this way, any change in the process is tested with initial simulation, preventing disruption in actual performance.

Conclusion and Summary

Process simulation is a vital tool for predicting, analyzing, and improving organizational performance before execution. This approach, by combining technology, data, and analysis, enables organizations to make their strategic decisions with less risk and greater accuracy.

By leveraging simulation within the framework of Business Process Management (BPM), organizations can not only enhance their operational efficiency but also lay the foundation for a data-driven decision-making culture and sustainable digital transformation.

Frequently Asked Questions

The ability to test different scenarios without the cost and risk of actual execution.