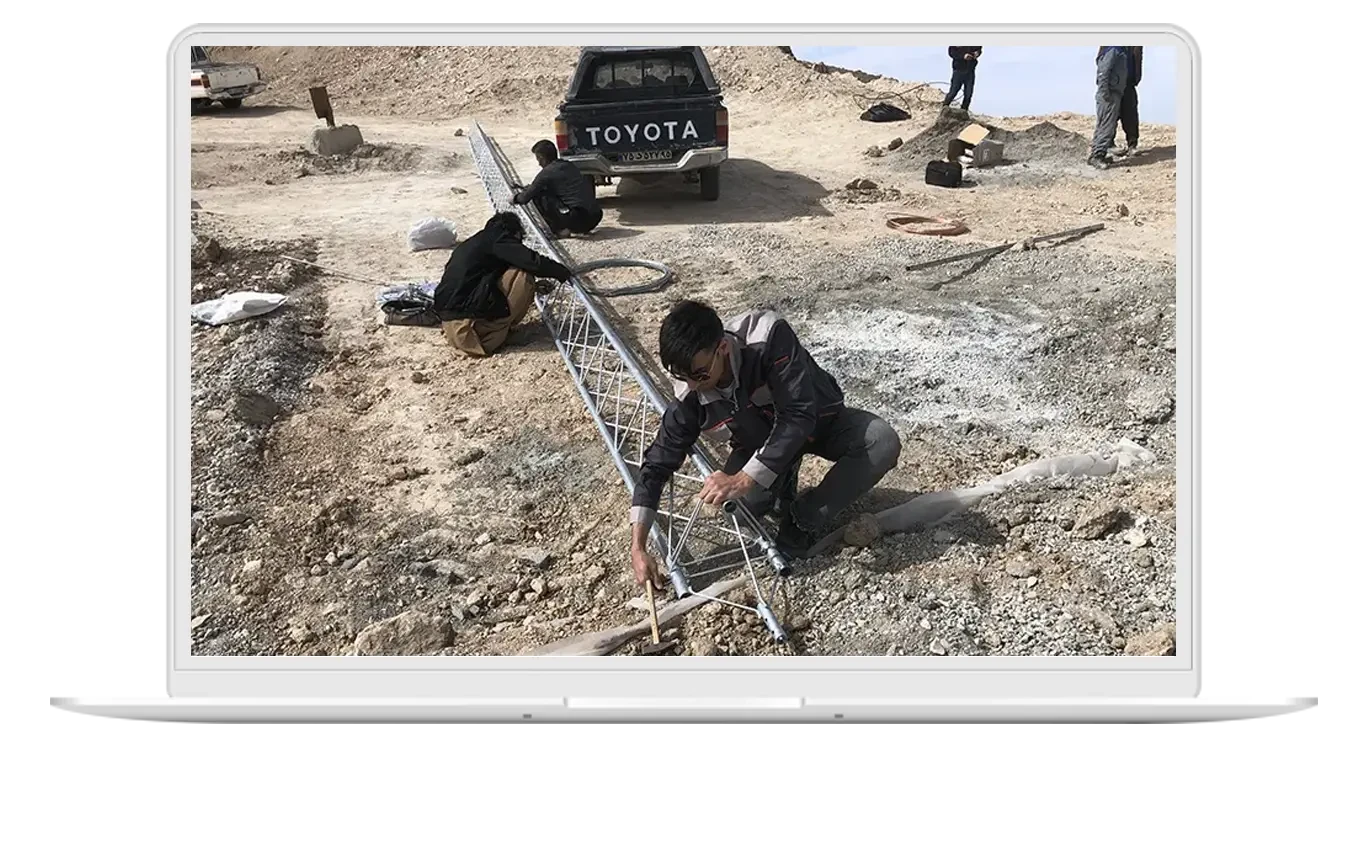

An Introduction to the Communication Infrastructure Project of the Madofti Gold Mine

In the mining industry, creating sustainable communication infrastructure is one of the essential prerequisites for smart mining and leveraging modern technologies. In this regard, Pars Mining Development Company has implemented the mobile and wireless communication infrastructure project at the Madofti Gold Mine through the construction of telecommunications towers. This project, in addition to increasing communication access across the mine, provides the necessary platform for entering the phases of Internet of Things (IoT), Artificial Intelligence in Predictive Maintenance, and Maintenance Management System in the Manufacturing Industry.

Key Objectives of the Project

- Establish comprehensive communication coverage within the mine area

- Facilitate communications between operational and managerial sections

- Create infrastructure for Internet of Things (IoT) projects

- Prepare the platform for implementing Artificial Intelligence in Predictive Maintenance

- Enhance efficiency by deploying Maintenance Management System in the Manufacturing Industry

Challenges Before the Project

- Lack of stable communication coverage across the mine area

- Issues in operational and supervisory data exchange

- Inability to monitor equipment and machinery in real time

- Dependence on traditional methods for reporting and maintenance

Achievements of the Project Implementation

- Launch of mobile and wireless platforms within the mine area

- Increased data transfer speeds and communications

- Creation of a secure platform for future projects

- Enhanced organizational agility in mining operations management

The Role of Infrastructure in the Development of Smart Technologies

The Role of Internet of Things (IoT) in Maintenance

The establishment of a stable communication infrastructure has laid the groundwork for connecting mining equipment to Internet of Things (IoT). This capability enables real-time monitoring of machine status and predicting maintenance needs.

Artificial Intelligence in Predictive Maintenance

By transferring real-time data through the network, Artificial Intelligence algorithms can be employed to analyze data and execute predictive maintenance. This will reduce unexpected downtime and increase the lifespan of equipment.

Maintenance Management System in the Manufacturing Industry

The created infrastructure facilitates the deployment of a Maintenance Management System in the mining environment. This system allows managers to analyze equipment performance and optimize preventive and corrective maintenance plans.

Conclusion

The creation of communication infrastructure for the Madofti Gold Mine is a strategic step towards the smart mining of the country. This infrastructure, in addition to resolving existing communication issues, has paved the way for the introduction of advanced technologies such as Internet of Things, Artificial Intelligence in Predictive Maintenance, and Maintenance Management System in the Manufacturing Industry. As a result, the Madofti mine has now become a model for other mines in the field of digitalization and smart operation.

Frequently Asked Questions (FAQ)

1. What was the main objective of building the tower and creating communication infrastructure in the mine?

To create mobile and wireless communication coverage to enhance data exchange speed and prepare for smart mining.

2. What is the role of the Internet of Things (IoT) in this project?

IoT enables real-time monitoring of equipment and identifying problems before serious failures occur.

3. How does artificial intelligence work in predictive maintenance?

By analyzing real-time data from equipment, AI identifies failure patterns and alerts before problems occur.

4. What role does the maintenance management system play in the mining industry?

The maintenance management system organizes and optimizes maintenance and repair programs to increase equipment productivity.

5. Is this infrastructure usable in other mines as well?

Yes, this communication infrastructure model can be implemented in other mines and similar industries.

6. What impact does this project have on the digital transformation of mines?

This project is a fundamental step towards the digitalization of mines and moving towards smart and sustainable operations.